OUR OEM EXPERTISE IS YOUR ADVANTAGE

Setting the standard in mill relining excellence since 1985, no one knows the potential of your equipment to improve safety and mill availability like RME. Leverage our 35+ year OEM history, global site expertise and data-driven insights to your advantage. Access local and personalised 24/7 technical support wherever you are in the world – at every lifecycle stage.

ASSET SUPPORT AND OPTIMISATION

Acquiring the best-performing equipment is only part of the story. What makes working with us unique is not just our broad asset support offerings, but the application of insight, process and technology for improved relining speed and safety. From certified training and major servicing to full-scope optimisation partnering, is why our Customers say ‘it’s ‘RME for me’.

Order a MILLMAST Powershift Mill Liner Handler before 30 November 2022 and receive a complimentary THUNDERBOLT 250 Recoilless Hammer for a comprehensive ‘out of the box’ mill relining solution!

MILLMAST Powershift is tailor-made for smaller mills, especially those unable to accommodate a mill relining machine due to mill space or economic constraints. MILLMAST Powershift overcomes these challenges by being the industry’s most compact liner handler that is swift to set-up, low cost and easy to operate.

Features and benefits abound:

Faster mill relining – Reach more liner rows with less inching cycles

Far safer – Eliminates all manual liner lifting and reduces crew inside the mill

Light yet robust – Carry by hand into the mill and handle liners to 400kg

Easy-to-use – Crews love it’s easy assembly and pendant control

Versatile – Use across multiple mills (up to 18ft diameter) for higher return on asset usage

Economical – Low capital outlay and reduced shutdown costs

What’s more, pair it up with a THUNDERBOLT 250 Hammer for faster liner bolt removal and safety. With its reliable second-by-second 250 joule strike you can do away with inefficient sledge hammering and risk of injury.

To secure your MILLMAST Powershift bundle offer:

1. Register for this no obligation offer via the button below.

2. Receive a confirmation email and more information on RME's fast, reliable, safe technologies for space constrained mills.

3. Order your MILLMAST Powershift by 30 November 2022.

In the end, the fact remains that manual mill relining is unpredictably slow and inherently unsafe. So, make the easy shift to MILLMAST Powershift and THUNDERBOLT 250 Hammer today!

SMALL MILLS SOLUTIONS

MILLMAST POWERSHIFT

The MILLMAST Powershift is the in-mill erected liner handler which suits small to medium mills with high ball charge levels. Erected in minutes and able to handle liners weighing up to 400kg, MILLMAST Powershift eliminates all manual liner lifting. Power is sourced from the MILLMAST Powerpack placed outside the mill.

MILLMAST MAX

The MILLMAST MAX Mill Liner Handler is an efficient relining solution for Ball mills with liners up to 400kg and sufficient free space at one end of the mill. By removing the need for manual lifting, MILLMAST MAX delivers an affordable and reliable way to boost productivity and crew safety.

RUSSELL 3 1000

The RUSSELL 3 1000 Mill Liner Handler is designed for mills with sufficient free space at one end of the mill and with liners up to 1000kg. The RUSSELL 3 1000 offers a value for money, standardised design solution backed by legendary RME reliability and after sales service.

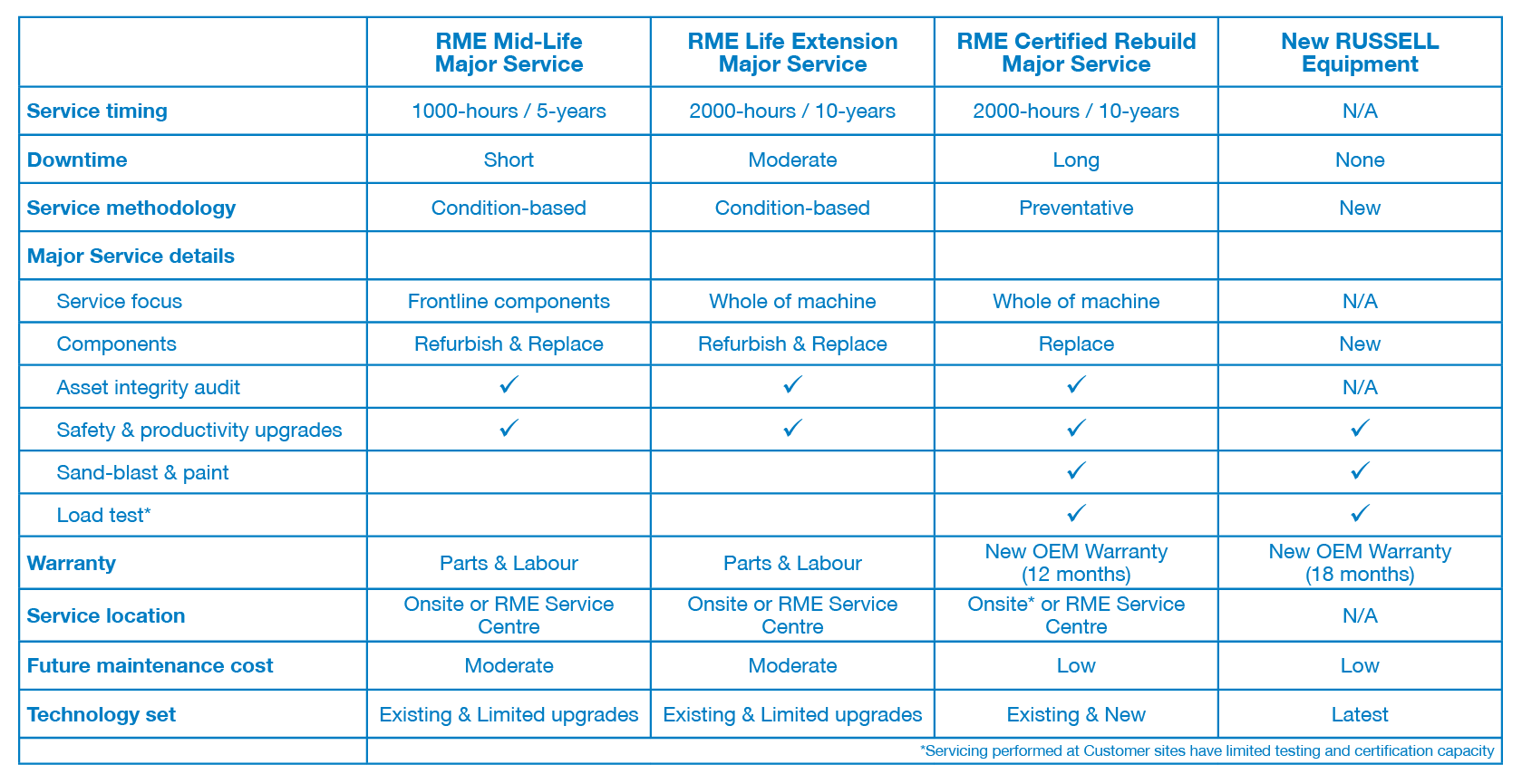

RME MAJOR SERVICES

RME MID-LIFE MAJOR SERVICE

An RME Mid-Life Major Service is a sound investment in the ongoing reliability of your RUSSELL equipment. This type of condition based maintenance servicing ensures your RUSSELL Mill Relining Machines, RUSSELL Mill Liner Handlers and RUSSELL Feed Chute Transporters are ready to perform to their full potential for a safe and reliable reline.

RME LIFE EXTENSION MAJOR SERVICE

An RME Life Extension Major Service will extend the operational life, improve safety and increase productivity of your RUSSELL equipment. A Life Extension Service ensures that all equipment components, are inspected, tested, refurbished and replaced, if required. This service is designed to extend the life of your current asset, keeping it functioning efficiently and safely.

RME CERTIFIED REBUILD MAJOR SERVICE

An RME Certified Rebuild Major Service will help you achieve full utilisation and a second life for maximum lifetime value for your RUSSELL MRM. An RME Certified Rebuild is an eco-friendly option that sustainably rebuilds your machine, allowing your mine site to reuse your RUSSELL MRM and get new machine performance for less than a new purchase.

SEE WHAT MAJOR SERVICE IS RIGHT FOR YOU

Download our RME Major Services comparison table to see what is included in each service and which is best suited to your needs!

CONTACT US

To speak with one of our mill relining experts about your RUSSELL equipment or servicing requirements, you can call our office on the numbers listed below or contact us by email using the form below.

Toowoomba

2 Russell Street

Toowoomba City, Toowoomba

Queensland, Australia

P +61 7 46 989 100

Perth

Unit 3, 73 Discovery Drive cnr Tidal Way

Bibra Lake

Western Australia, Australia

P +61 7 46 995 712

Service Offer - Terms and Conditions

1. Offer only valid in the participating region/country. Offer region/country excludes North America, South America, Africa, Russia, China and Iran. 2. Equipment must be located in participating region/country. 3. Online registration open 30-days from date of sending of eDM or until 30 November 2022. 4. Can only be offered 1/mine site or sales order. 5. Offer cannot be combined with any other promotion or discount. 6. Purchase order must be received by RME within 3-months of registration for offer. 7. Offer cannot be redeemed against an already processed order. 8. Limit of five regional offers redeemed by any one site. 9. RME’s Standard Site Service & Optimisation Terms & Conditions apply on all quotations/orders. 10. Offer can be subject to change or withdrawn by RME at any time.

© 2022 RUSSELL MINERAL EQUIPMENT